Heat Trace Cable Installation Guide

208 volts 277 volts 2703 2 75 1 28 2705 2 86 1 16 2708.

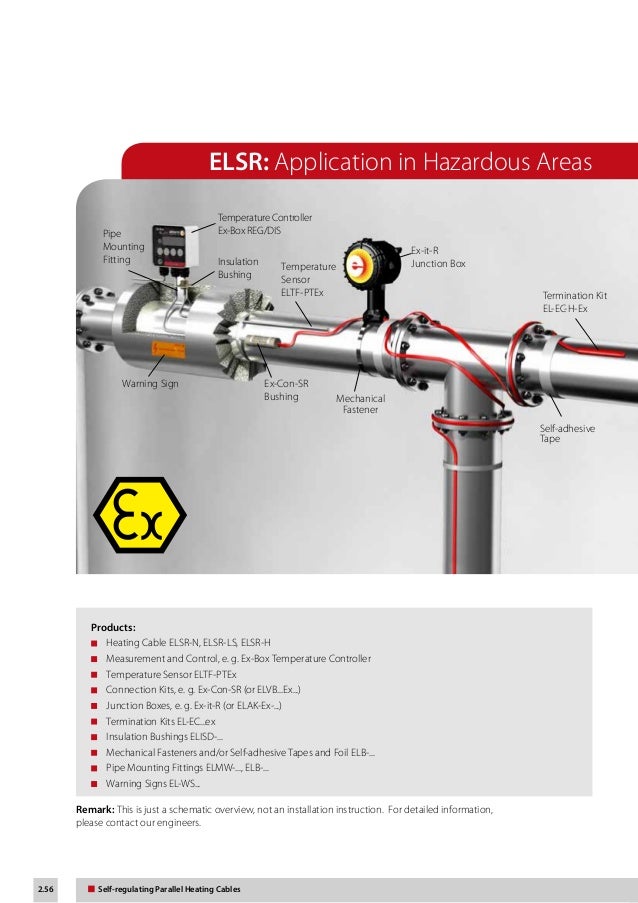

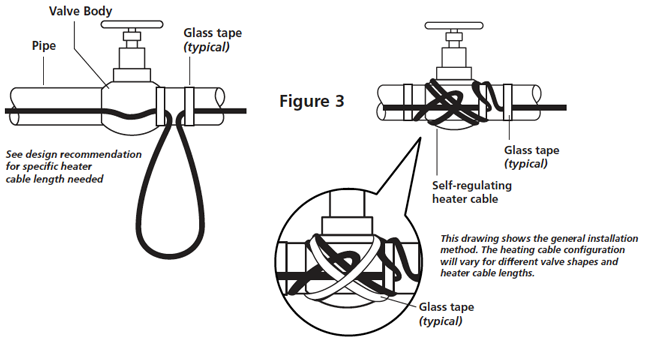

Heat trace cable installation guide. These heat tracing cables consist of a conductive polymer heating matrix extruded between two parallel copper bus conductors. Have been hydrostatically tested prior to the installation of the heating cable. Of heating cable required to efficiently heat trace pipes valves and flanges. Heat trace the demands placed on heat tracing systems vary based on the design parameters specific to each application.

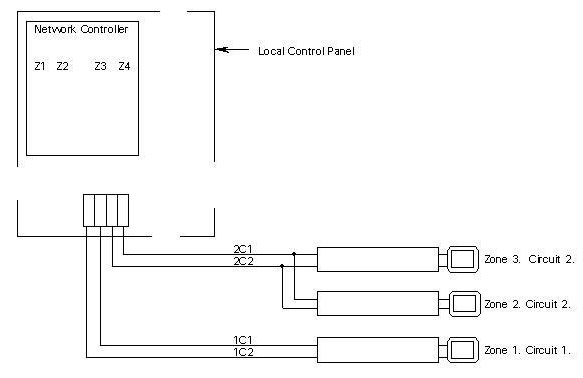

Nvent unveils wireless communication heat tracing solution london business wire nvent electric plc nyse nvt nvent a global leader in electrical connection and protection solutions today announced the launch of the nvent raychem elexant 9200i wireless communications interface. The canadian electrical code requires that all heat tracing applications utilize. To meet these needs thermon manufactures the widest variety of electric heating cables and control systems in the world. Refer to installation instructions included with cable termination kits or contact thermon for specific instructions to fabricate heating cable.

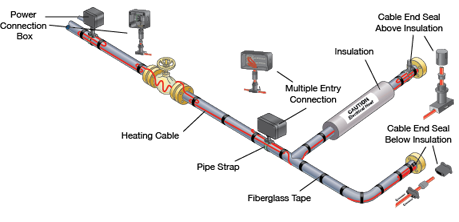

Heat tracing systems comprise heating cables and ancillary items which necessarily interface with other system components such as thermal insulation and the electrical supply items which will power the system. Heat is generated in the conductive. Always install tracing at the 5 or 7 o clock position on a pipe. Sensor location heating cable typical pipe wall.

Walk the system and plan the routing of the heating cable on the pipe. Power adjustment factor part no. Selection of heating cable type and rating should be in accor dance with the procedures located in the chromalox design guide for heat tracing products. Complete the pipe pressure test.

An insulation resistancetest on each reel is recommended. Check piping to be traced. Inspect heating cable and components for in transit damage. Alternate voltages rscc 240 vac self regulatingheating cables can be operated at alternative voltages.

Each heat tracing application imposes unique demands on the designer to achieve the desired performance in a safe manner. The chart below compares heating cable power output with prod uct rating. Termination kits to fabricate a heat tracing circuit are not addressed in detail in these installation procedures.